SikaGrout 212 Fluid – Grouting mortar – 25 kg – Grey

SikaGrout 212 Fluid is a ready-to-use, cement-based grouting mortar designed for leveling, anchoring, and filling applications in concrete structures. It is commonly used in construction projects to secure equipment, anchor structural elements, and fill voids, offering high mechanical strength, excellent fluidity, and quick setting.

129,99€ TTC

SikaGrout 212 Fluid is a ready-to-use, cement-based grouting mortar designed for leveling, anchoring, and filling applications in concrete structures. It is commonly used in construction projects to secure equipment, anchor structural elements, and fill voids, offering high mechanical strength, excellent fluidity, and quick setting.

Characteristics of SikaGrout 212 Fluid

Product Type:

- Single-component, ready-to-use cement-based grouting mortar modified for enhanced fluidity.

Main Applications:

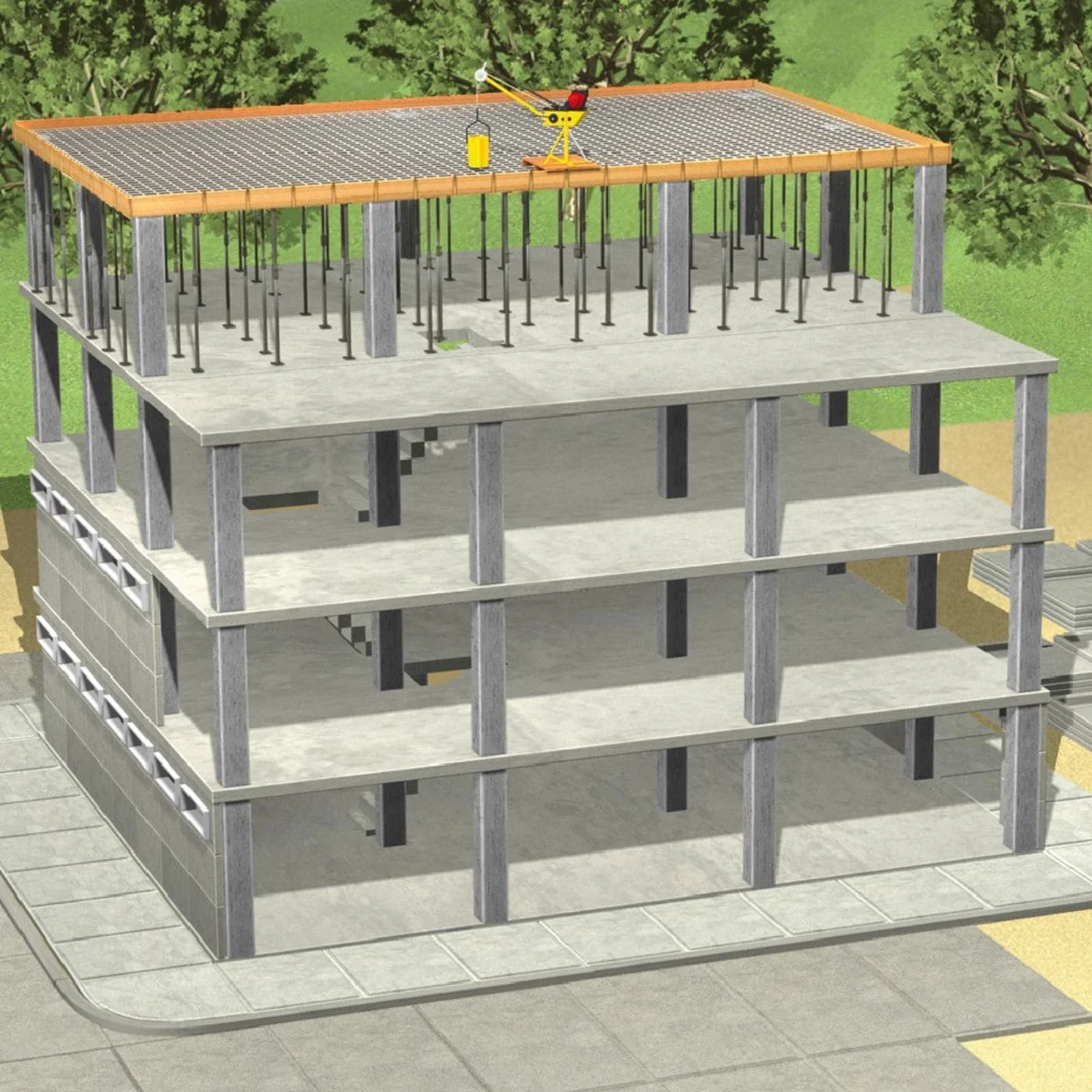

- Machine and Equipment Anchoring: Suitable for leveling and anchoring heavy structures like turbines, motors, or guide rails.

- Structural Anchoring: Anchoring of poles, steel beams, or bridge supports.

- Cavity and Gravel Nest Filling: Used to fill cavities in existing concrete and correct pour defects.

- Sealing Prefabricated Elements: Ideal for assembling precast concrete structures.

Technical Properties:

- Fluidity: High flowability, enabling easy filling of voids and reaching hard-to-access areas.

- Compressive Strength: Very high, reaching up to 65 MPa after 28 days, ensuring excellent load-bearing capacity.

- Controlled Expansion: Compensates for shrinkage to provide complete, crack-free curing.

- Setting Time: Begins to harden in a few hours depending on temperature, achieving full set in 28 days.

- Adjustable Consistency: Consistency can be modified by varying water content, allowing for a more fluid or firmer grout depending on application needs.

Consumption:

- Approximately 2 kg/m² per millimeter of thickness applied, depending on the mix density and added water quantity.

Application Temperatures:

- Recommended application between +5°C and +30°C. Take precautions in high temperatures to avoid overly rapid setting.

Packaging:

- Available in 25 kg bags, making it easy to transport and dose according to needs.

Storage and Shelf Life:

- Store in a dry place between +5°C and +35°C, protected from moisture.

- Shelf life: Up to 12 months in original, unopened packaging.

Advantages of SikaGrout 212 Fluid

- High Mechanical Strength: Ensures excellent durability and stability under load.

- Easy Application: Ready to use, only requires water for mixing, and is easy to pour.

- Controlled Expansion: The formula minimizes shrinkage, reducing the risk of cracking and delamination.

- Versatile: Suitable for both indoor and outdoor environments, even under dynamic load.

- Concrete Compatibility: Composition compatible with concrete structures, reducing behavioral differences between materials.

Application and Precautions

- Surface Preparation: Ensure a clean, particle-free, grease-free, and dust-free substrate for better adhesion.

- Mixing: Mix with water as per manufacturer’s instructions. Avoid excess water, which may affect mechanical properties.

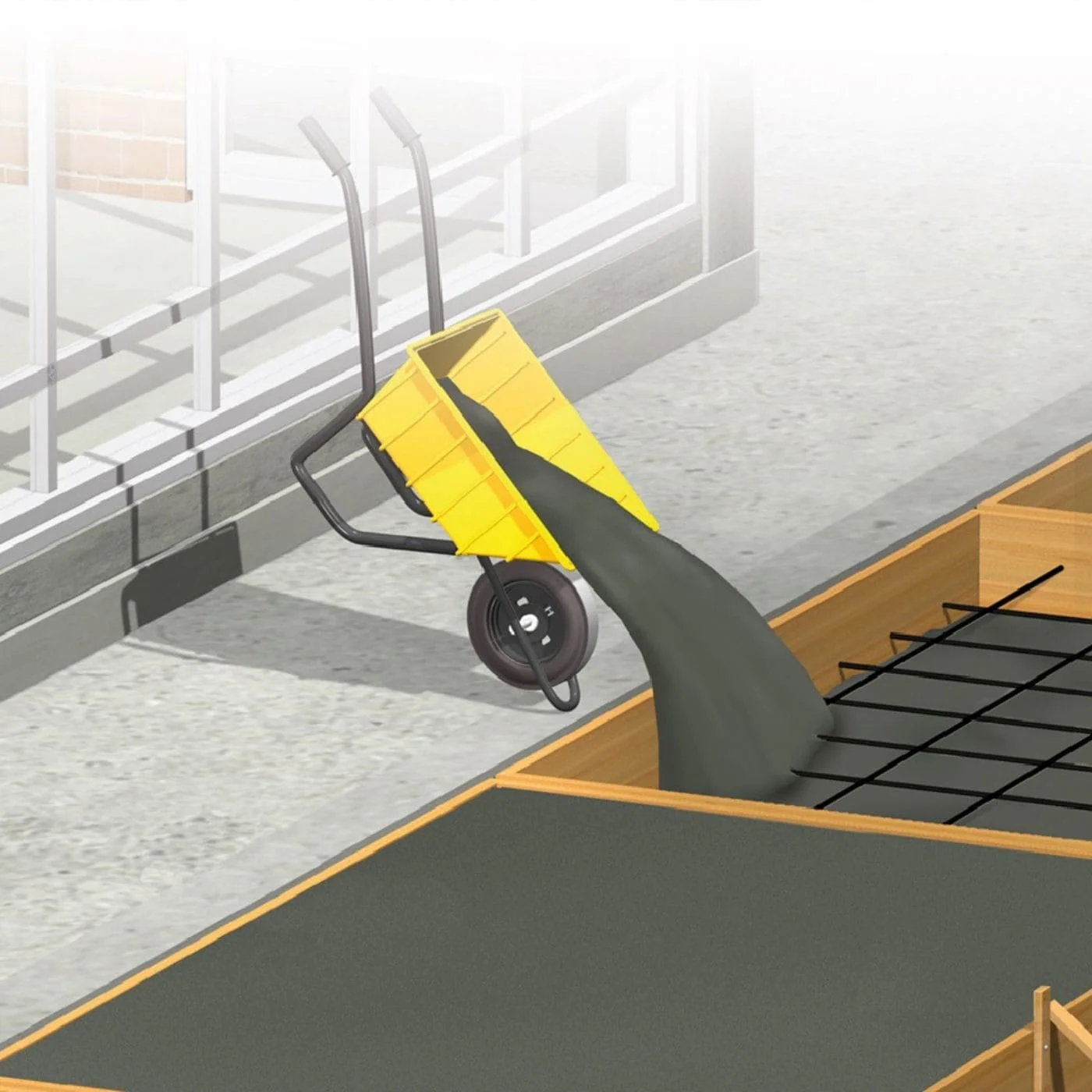

- Application: Pour directly into cavities or around elements to be sealed, taking care to remove air bubbles.

- Curing: Take measures to keep the grout moist during the initial days to ensure optimal set and minimize shrinkage.

Technical Characteristics of SikaGrout 212 Fluid

Compressive Strength:

- After 1 day: Approximately 20 MPa

- After 7 days: Approximately 50 MPa

- After 28 days: Approximately 65 MPa

These high values ensure excellent load-bearing capacity for heavy equipment and structures.

Controlled Expansion:

- Expands during initial setting to counteract shrinkage and provide a complete, homogeneous seal.

Consistency:

- Fluid to plastic grout: Adjustable based on water quantity used, facilitating void filling and adhesion to structures.

Consumption: Approximately 2 kg/m² per millimeter of applied thickness.

Density:

- Mix density: Approximately 2.2 kg/L

Setting and Hardening Time:

- Initial Setting Time: Between 3 to 5 hours (depending on ambient temperature).

- Full Curing: Achieved in 28 days for maximum mechanical performance.

Adhesion to Substrate:

- Strong adhesion to prepared concrete surfaces, preventing detachment and ensuring stability under mechanical loads.

Application Temperature:

- Recommended range between +5°C and +30°C.

- In high temperatures, maintain product moisture to prevent overly rapid setting.

Pot Life:

- Must be applied within 30 to 60 minutes after mixing, depending on temperature and humidity conditions.

Modulus of Elasticity:

- High, ensuring good compatibility with concrete structures and allowing for deformation absorption without cracking.

Standards and Certifications:

- Compliant with sealing and anchoring standards for structural applications in concrete, guaranteeing work quality and safety.

Additional Properties

- Chemical Resistance: Good resistance to oils and moderate industrial chemicals, ideal for industrial settings.

- Compatibility with Steel and Concrete: Bonds effectively to steel and concrete surfaces, allowing for a strong and durable connection.

Precautions and Storage Conditions

- Storage: Keep in a dry area at a temperature between +5°C and +35°C, away from moisture.

- Shelf Life: Up to 12 months in original, unopened packaging when properly stored.

Conclusion

SikaGrout 212 Fluid is a high-quality, robust, and easy-to-use grouting mortar designed for demanding sealing applications. Its high strength, fluidity, and controlled expansion make it ideal for securing heavy equipment and rehabilitating concrete structures, delivering durable performance for industrial and structural applications.

Click here to access all our Sika products.

Follow us on all our social networks to keep up to date with all the news from our site!

| Weight | 25 kg |

|---|

Related products

-

SikaCeram 650 Classic – Porcelain mineral seal – 5 Kg – White – Cement

49,99€ Select options This product has multiple variants. The options may be chosen on the product pageRated 0 out of 5 -

12 Pack of SikaFlex 112 Crystal Clear Sika – Multipurpose Transparent Adhesive and Sealant – 290 cm³

299,99€ TTC Add to cartRated 0 out of 5

Reviews

There are no reviews yet.